SIAC is THIS

Production

Done for you. Manufactured by us.

SIAC offers its Customers complete cabins and single components through a internal vertical process.

From moulding to automated welding, from painting to the final assembly, SIAC can guarantee a fully integrated process and the highest quality standards.

59.000+

Global annual production of cabins

3

Cataphoresis and painting plants in the World

5

Welding plants in the World

3

Assembly plants in the World

1.000+

ton/month of steel processed

Moulding and 3D Laser

Whatever you may need, piece by piece.

MULLER P 700 (hydraulic)

MULLER P 530 (hydraulic)

RADAELLI EXC T 600 (mechanical)

Laser Prima Industrie (Optimo 3500)

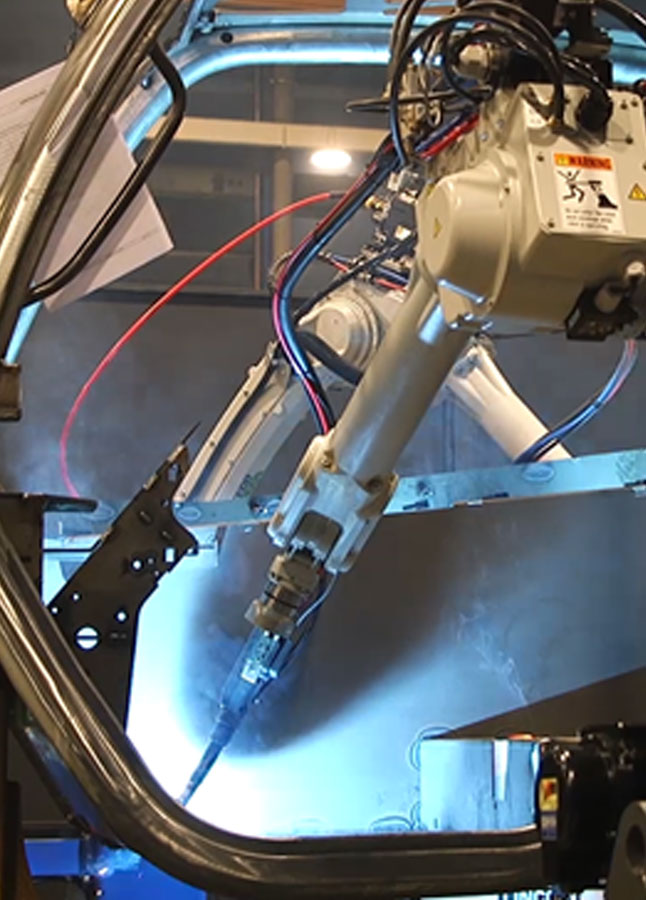

Welding

Masters of manual and automated welding.

100% of our cabins are processed through one of our automated welding stations.

Painting

One standard. A thousand colors.

A 2.000 mm long, 1.700 mm wide, and 1.900 mm deep cataphoresis system.

Two powder coating plants.

Assembly

In Europe we assemble one cab every 5 minutes.

SIAC Italy:

Over 100 cabs assembled every day;

5 multi-product assembly lines;

5 single-product assembly stations;

Over 50 different models assembled every day.